Steel can be produced via two main processes: either using an integrated blast furnace (BF)/ basic oxygen furnace (BOF) or an electric arc furnace (EAF). As the predominant production method in Europe is the conventional, coal-dependent BF/BOF process, the need to assess alternative breakthrough technologies to reduce carbon dioxide emissions is high. Studies over time have shown the presence of three main CO2 mitigation pathways: CDA (Carbon Direct Avoidance), PI (Process Integration) and CCUS (Carbon Capture, Usage and Storage). The pathway Process Integration is dedicated to the process modifications that are designed to be integrated in conventional steel plants.

One of the important options that was highlighted in this pathway is the injection of reducing gases, and especially H2-rich gases, in the BF to reduce coke rate and CO2 emissions. Gas injection in the BF is one of the main pillars of the Process Integration strategy, with a potential of 15-20% total mitigation.

In the 42 months of project duration, the five partners will face and solve several issues, with the main objective to adapt an existing pilot plant on industrial site to produce hot H2-rich syngas.

Actions:

- Laboratory tests will be conducted in order to characterize the feedstock materials (coke breeze and other non-fossil carbon sources), to test in small scale burning plant the characterized feedstock and make small scale pilot trials of COG reforming with hot CO2;

- Reforming model validation with data from lab tests and fine-tuning during pilot trials;

- Operating practices for pilot tests campaign will be designed based on outputs from reforming model validation;

- Partners provide the evaluation of industrial application potential by means of comparison of process performance in function of feedstock, definition of industrial operating points for a full-size equipment, safety analysis of use of syngas directly in BF tuyeres and comparison with direct injection of COG inside them, applicability of hot syngas in other steel facilities;

- Considering the scenario of combined reforming + BF injection at the tuyere, an LCA study will be done as well as economic feasibility of the process.

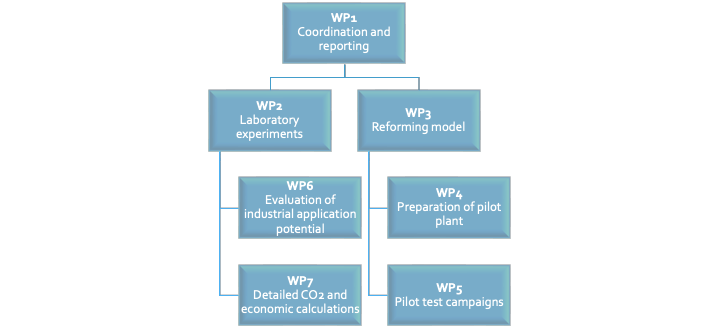

The activities are organised in 7 Work Packages, according to the traditional scheme of RFCS funded projects:

Partners TASKS:

- RINA-CSM is coordinator of the project, with a full-time project manager, and technical/financial reporting. Technical staff is employed for small scale burner tests and calibration and fine-tuning of reforming model. Besides support in WP4 and WP5, technicians and engineers are required in WP6 and WP7 for feasibility study and flexibility analysis of pilot plant.

- PW is mainly dedicated to detail engineering of coke breeze grinding and feeding system, along with support to evaluation of results and other general tasks.

- PWIT is dedicated to detail engineering of the pilot adaptation for coke breeze use, relevant procurement activities, supervision to erection and commissioning, as well as execution of the test campaigns on site and results analysis.

- CRM is mainly dedicated to laboratory analysis, production of alternative carbon materials, results interpretation, evaluation of industrial application potential, as well as CO2 impact and economic assessment.

- AM is mainly dedicated to project management, to supervise the pilot plant trials and results exploitation, study the comparison of the influence of injecting COG vs reformed gas, collaborate on the fine-tuning of the kinetic/CFD models, study the associated safety issues, analyze of alternative uses for the syngas, collaborate on the Carbon balance and economic calculation, and to state the project conclusions.

- AdI is mainly dedicated to Blast Furnace model calculation, feasibility studies, and historical industrial data collection. It is also involved into a database acquisition for supporting the LCA study.

The batch furnace operated by CRM Group is composed of a refractory-lined cylindrical chamber of 18 inches diameter heated either by a gas burner located in an adjacent chamber or by a top electrical heater. Nitrogen, air and steam injections are available. This furnace is able to simulate the atmospheric thermal treatment of solid grains or sludge where the behaviour of the material under treatment can be observed and sampled. The material bed is mixed by rabbling arms rotating on a vertical axis.

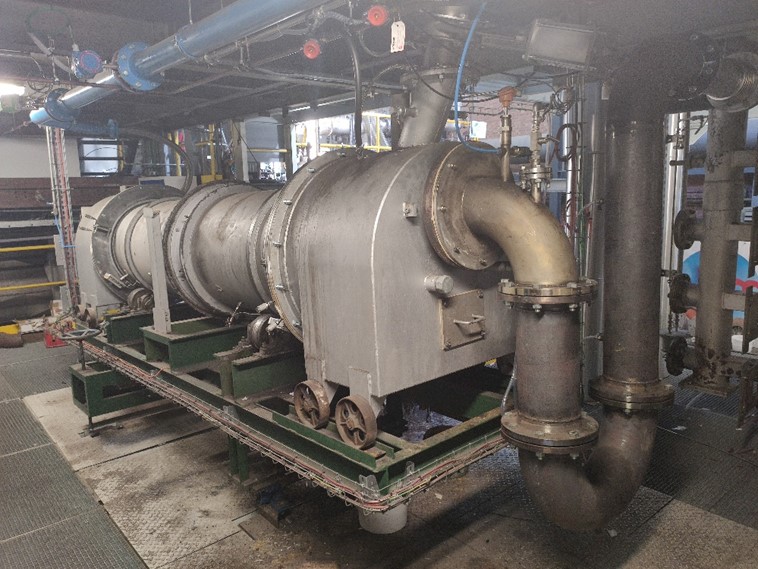

The rotary kiln of CRM Group is manly composed of a refractory-lined horizontal rotating drum (3.3m length, 0.5m diameter) heated by a gas burner at one of its end or by an internal electrical radiant tube. Raw materials are continuously supplied from a big-bag emptying station through a chain conveyor and a lock hopper. Hot product is cooled down and recovered in a weighted barrel. Drum tilting, rotation speed and temperatures can be adjusted and are monitored. Reductive or oxidative conditions can be achieved. Air and nitrogen injections are available.

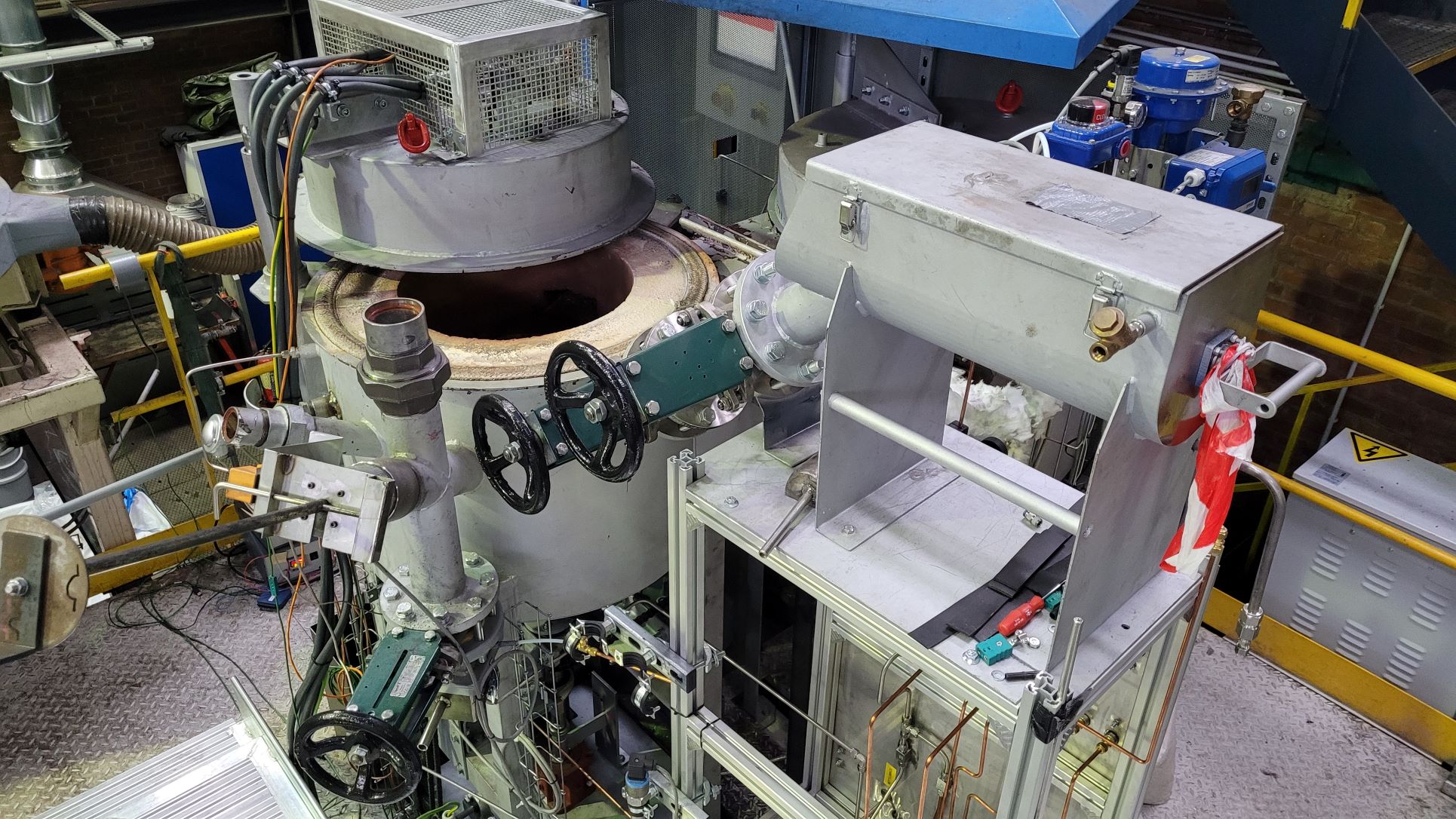

Panoramic view of Italiana Coke production site, located in Cairo Montenotte (SV), Italy, where the "coke breeze" pilot plant will be hosted.

View of the existing "tar" pilot plant, from combustion chamber up to reforming reactor, post-combustor and fumes stack. This will be adapted to treat coke breeze, by adding coke breeze transportation and injection system, oxy-coke-breeze burner, as well as complementary adaption to the relevant sections.